Unlocking Efficiency in Education: New Fixturing System Revolutionizes CMM Process for Students

With the ever-evolving challenges faced by educators in training the next generation of machinists, the need for adaptable and versatile inspection solutions becomes increasingly apparent. Instructor Gabrial Kooyers writes about Inspection Arsenal's® transformative impact on the inspection process at Van Buren Tech (Lawrence, MI) -- an advanced manufacturing class that uses the Titans of CNC Academy.

Traditionally, inspecting student-produced parts in a manufacturing education environment has been a cumbersome process. The absence of fixtures and gauges often necessitated time-consuming methods much as hot gluing parts to tables. This not only consumed valuable instructional time but also hindered the fluidity of the learning experience.

Recognizing this challenge, Van Buren Tech sought a solution that would provide both accuracy and efficiency in the inspection of student parts.

The Solution

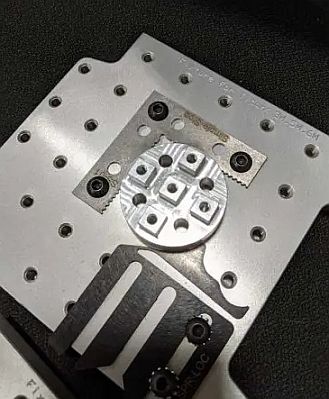

Inspection Arsenal® is a versatile and innovative fixturing solution designed to address the unique needs of manufacturing inspection. The system is built with adaptability in mind, allowing for quick-swaps and repeatable inspection of a variety of parts without the need for time-consuming setup changes.

VIDEO: Inspection Arsenal® -- Lean Quick Swap Modular Inspection Fixturing

Implementation at Van Buren Tech

At Van Buren Tech, junior and senior students follow the structured Titans of CNC Academy building block curriculum.

To elevate the inspection process, they've adopted the Inspection Arsenal® fixturing system. Guided by the Titans of CNC Academy's curriculum, students advance through distinct cutting phases, creating a variety of parts at different stages. In this personalized curriculum, the crucial need for seamless transitions between inspections is emphasized. The system has become a game changer in the quest for streamlined, individualized curriculum delivery.

Benefits of Inspection Arsenal®

Time Efficiency

The fixture plates, strategically organized on a shelf, have revolutionized workflow. Students can now grab a fixture plate and set up inspections within minutes, significantly reducing downtime associated with traditional methods. Students can finish their part on the CNC machine and inspect it with the Master 3D gauge CMM within minutes.

Adaptability

The versatility of Inspection Arsenal® permits inspection of different parts at any given moment, accommodating the dynamic nature of our individualized curriculum.

Ease of Use

The user-friendly design of the fixtures ensures that even students with minimal experience can set up inspections quickly and accurately, promoting a seamless learning experience.

Consistent Accuracy

Fixed prebuilt setups eliminate variability in the inspection process, ensuring consistent and reliable results across different parts and students.

Conclusion

Inspection Arsenal® fixturing has proven to be a transformative solution for the students at Van Buren Tech. It offers a streamlined and efficient method for inspecting student parts in a dynamic and individualized curriculum.

The system's adaptability, ease of use, and consistent accuracy have made it an indispensable tool in the pursuit of excellence in manufacturing education. As we continue to empower the next generation of machinists, the CMM Fixturing system stands as a testament to the impact that innovative inspection solutions can have on the learning experience.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy