Dual Contact Spindle System Increases Tool Rigidity; Compatible with Existing Standard Spindles

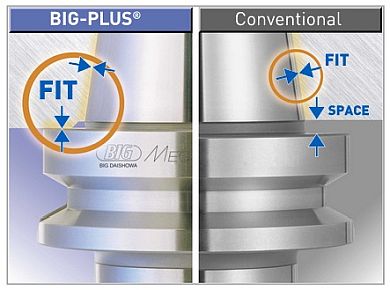

Big Daishowa's BIG-PLUS is a dual contact spindle system where the shank contacts the spindle taper and the spindle face simultaneously, resulting in increased tool rigidity.

Rigidity is greatly enhanced due to the larger contact diameter of the tool holder flange face. This larger face contact, combined with the taper contact, works together to resist deflection. With less deflection, greater machining accuracy and superior finish can be achieved.

The BIG-PLUS Spindle System assures the highest precision location of the tool holder in the spindle when using the ATC for loading tools as a result of the dual contact, which precisely positions the tool holder within 1 micron.

VIDEO: The BIG-PLUS Difference

BIG-PLUS dual contact tool holders can be used on existing standard machine spindles. Existing standard tool holders can also be used on BIG-PLUS spindles. In this case, however, simultaneous contact cannot be attained.

Although other simultaneous contact systems require exclusive new accessories, BIG-PLUS tooling uses existing accessories such as a tool presetter and tool holder fixture as it is based on a conventional steep taper shank. Further, it is not necessary to modify tool magazines and ATC devices of existing machines.

Other Benefits:

- Improved surface finish & dimensional accuracy

- Extended tool life

- Prevention of fretting corrosion caused by heavy cutting

- Improvement of ATC repeatability

- Elimination of Z-axial movement at high speeds

- Improved roundness of boring operations

Want more information? Click below.

Rate this article

View our terms of use and privacy policy