New Adjustable Chamfering Tooling Eliminates Burrs in Exotic Materials

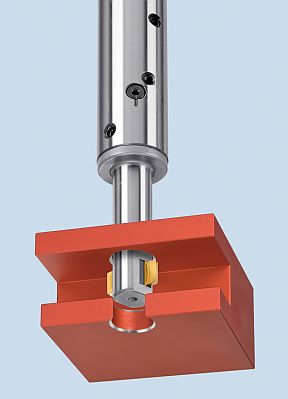

HEULE has introduced DEFA tooling, which provides a wide range of adjustment for chamfering operations in difficult-to-machine materials like Inconel, Titanium, 4140 Steel, and others with large burr formation.

Robust construction and an advanced dual-cutting system with exchangeable carbide blades enable front and back or back-only chamfering of bores from 4 mm to 36.2 mm (0.157" to 1.425"), to handle a wide range of machining requirements. Its unique blade geometry incorporates a sliding surface that enables chamfer cutting without compromising the integrity of the bore surface or interfering cross holes, ensuing surface quality.

DEFA enhances precision and streamlines machining processes by eliminating the need for spindle reversal or workpiece indexing. This ensures precision and consistency even in the most demanding applications, such as longitudinal grooves, cross-bores, and open bores with discontinuous cuts.

VIDEO: Heule's DEFA | Controlled Chamfering Tool with Infinite Adjustments

The DEFA Tool compensates for surface variation allowing constant chamfer sizes on unknown or cast surfaces. This versatility enhances efficiency, optimizes productivity, and reduces set-up times, making it ideal for chamfering applications on exotic materials such as Inconel, Titanium, Hastelloy, and other hardened materials.

Ideal for Shafts, Compressor cases, landing gear components, and other airframe structures and anywhere precision front and back chamfering of through holes is need. Automotive applications such as planetary gears with multiple surface variations and burr formation can also benefit from DEFA technology.

This unique dual-cutting tool provides machinists with precise control over chamfer sizes across a range of on-tool adjustments, yielding flexibility to accommodate diverse bore dimensions and project specifications. Featuring an exchangeable carbide blade set with a material-specific coating, the DEFA tool delivers consistent and reliable performance in challenging machining environments.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy