Innovative 3D Laser Snapshot Sensor Makes Accurate Part Inspection Easier than Ever

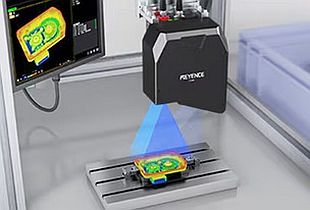

KEYENCE Corp. of America has introduced the next evolution in automated product inspection. The LJ-S Series 3D Laser Snapshot Sensors feature one-of-a-kind technology which makes accurate 3D inspection of parts easier and more accessible than ever before.

These sensors utilize a World's First Built-In Scanning Mechanism to generate accurate 3D images of stationary parts, which can be used for tolerance checks, defect detection, visual inspection, and so much more. The innovative design of the LJ-S Series ensures consistent and stable images, provides valuable height-based data, and eliminates the need for motion.

Consistent and Stable Images

The LJ-S Series of 3D Laser Snapshot Sensors are calibrated measurement devices that provide consistent images regardless of lighting, focus, environment, and more. When using conventional camera-based inspection systems, specialized lighting and lensing are necessary to dial in the inspection image. These images can then be different from location-to-location if the environment or position of the part changes.

With the LJ-S Series, these concerns are no longer an issue due to the built-in high-intensity blue laser light source, which is used to scan the target and generate the image. This means that if the target is within the detection range of the sensor, it will generate consistent and stable images every time regardless of lighting conditions, position changes, background, etc.

Benefits of Height-Based Inspection

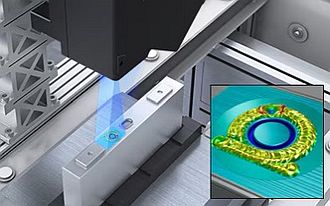

The LJ-S Series expands on conventional flat 2D inspections by adding precise height data to exponentially increase the level of inspection that can be achieved. Not only can all standard dimensions be checked with a high degree of accuracy, but dimensions like volume, step height, curvature, etc. can now be checked as well. This is extremely beneficial when looking at sealant or adhesive application to ensure that the volume applied is sufficient.

Along with this, height-based information allows for high-level defect detection regardless of the surface appearance or texture. Dents, divots, scratches, and other defects can now be detected easier and more consistently than ever before by utilizing the LJ-S Series.

No Motion Required

The LJ-S Series utilizes the World's First Built-In Scanning Mechanism to generate accurate 3D images without the need for part or sensor motion. Conventional laser profilers can generate accurate 3D images, but it is necessary for the part or sensor head to be moving. Adding motion required high precision stages, encoders, or drives to perform accurate inspections.

The LJ-S Series not only eliminates the need for these additional items, but also eliminates their impact on the overall accuracy of the setup. This means that the LJ-S Series provides higher quality images at a heavily reduced integration cost.

The LJ-S Series of Laser Snapshot Sensors represents the next evolution in part inspection. The one-of-a-kind design ensures a level of detection and inspection that is unmatched by conventional systems.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy