4 Tooling Strategies to Reduce Vibration in Boring Operations

Vibration is a slippery slope. You could have the ideal tooling setup for a given application and still encounter unforeseen issues. In precision boring operations, vibration can slow you down, cause excessive tool wear and even result in scrapped parts.

The specific factors that can contribute to vibration are myriad -- but Matt Tegelman, Senior Product Specialist at Big Daishowa Inc., describes four ways to minimize the problem.

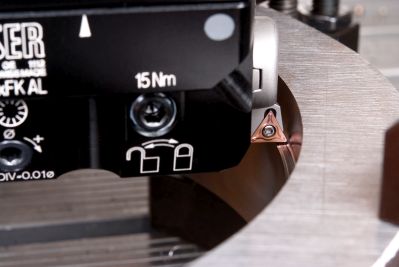

Big Daishowa offers a range of boring inserts, including pressed and ground-geometry, designed to optimize performance and extend tool life.

The fight against vibration starts at the machine, but what if your machine tool isn't quite a spring chicken? For older machines and applications that require extremely tight tolerances, tooling tech can go a long way.

Choose the Best Anti-Vibration Tech

Big Daishowa's EWN Smart Damper, for instance, combats vibrations and reduces chatter in deep-hole finish boring. The Smart Damper works via a passive damping mechanism that counters vibration with high-resonance friction action. Smart Damper components are designed to be modular -- enabling longer tool assemblies that address vibration as close to the cut as possible.

The EWN Smart Damper is designed for precision deep-hole machining, allowing for high cutting parameters that result in extremely short cycle times, improved surface finishes, and enhanced metal removal rates.

It's not just for a better finish -- the Smart Damper system enables higher speeds and feeds to improve cycle times by up to a factor of ten.

Think Smart with Modular Solutions

Common logic tells us that modular tooling can cause problems with rigidity. It's true that when using modular tooling systems to achieve extension, fewer connections are better. But in complex and deep-hole boring operations, longer tools may be inevitable. Here are several approaches to modular tooling can reduce vibrations:

- Lighter, higher-precision modular parts combat issues with tool assembly weight, reducing vibration and tool-change issues. Big Daishowa modular tooling allows greater flexibility with modular connections without compromising precision.

- In specialized cases, a different type of modular assembly can help: adding a guide bushing around the tool to guide the tool in the hole in a more rigid way. This solution calls for slower cutting and careful observation, so seek application support from a trusted tooling partner.

- Don't get your modular tooling from just anywhere -- each piece of a modular system must be even higher quality and more rigid than single-tool solutions to make up for the incremental loss in rigidity as connections are added.

Modular components are based on a cylindrical connection with radial locking screw. The CK modular precision tool system has continuously evolved to meet customer needs and adapt to the increasing performance of a machine tool.

Compensate with Digital Boring Heads

For boring applications that require tight tolerances, or where challenges increase the risk of oversized or undersized holes, digital boring heads can offer a bit of insurance and significantly speed up production.

The EWE 2-152 digital fine boring heads seamlessly connect to Big Kaiser's user-friendly smartphone and tablet app. This integration simplifies the process of monitoring and configuring the boring head during the assembly and operation of boring tools.

Digital boring heads allow operators to make high-precision adjustments faster and easier. What's more, models like the EWE 2-152 digital fine boring head allow for variable length adjustment of the tool holder for the shortest, most rigid tool assembly.

VIDEO: Using the EWE 2-152 with the BIG KAISER App

Select the Right Insert

The right tooling insert to reduce vibration in boring is a high-quality, ground insert with a sharp cutting edge to reduce tool pressure. Beyond that, lead angles matter. Longer lead angles may allow you to increase speeds and feeds, but lead angles closer to 90 degrees apply the least amount of radial pressure against the tool. Less pressure means less vibration -- and better productivity and tool life.

Minimizing vibration to achieve optimal results and productivity is a team effort -- not only from the many physical components at play, but application experts who can help guide your team to the best solution.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy