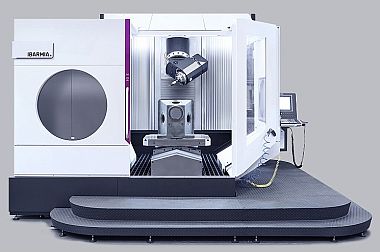

Ibarmia's Extreme 5-Axis MC Offers Continuous Production in a Small Footprint

Ibarmia's THC 12 EXTREME machining center is designed to maximize productivity through smart automation and robust 5-axis performance. Equipped with a rotopallet or twin pallet system, this machine allows continuous operation: while one pallet is being machined, the next part is prepared, significantly reducing idle time and optimizing overall workflow.

Its electrospindle delivers an impressive 84 kW and 12.000 rpm, making it ideal for a wide range of materials, from light alloys to high-performance superalloys. According to the company, this level of power, combined with a high level of precision, ensures top results even in the most demanding applications.

The configuration with a continuous tilting head and rotary table provides full 5-axis machining capabilities, giving the user complete access to complex geometries in a single setup. This means faster cycle times, fewer setups, and enhanced machining accuracy.

Despite its high performance, the THC 12 EXTREME maintains a compact footprint, making it an excellent solution for manufacturers looking to maximize output without expanding their shop floor.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy